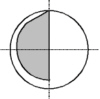

Cross section

halfened

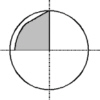

Cross section quarter round

|

Halfened

or quarter round?

The classical bits are halfend. In the

last years however a lot of users began demanding quarter rount bits.

Why?

Advantages:

1.

Better chip removal due to the "more open" shape. Better

cutting results as the chips cannot be pressed against the material by

the back of the tool. This leads to better surfaces especially when

cutting aluminium or acrylic.

2.

Rotation spees and feed rate can be raised by 20 - 30%, especially

within plastic material.

3.

Less out-of-balance forces and thus less vibration caused by the tool as

the excentric mass is reduced and the center of gravity moves closer to

the axis of the tool.

Disadvantage:

1.

The tip of the tool becomes weaker and breaks more easily. This however

should affect only tools with small width (b <= 0.20 mm)

or tools used with machines with little rotation accuracy or little

stiffness.

Coating engraving

cutters?

Yes. The advantages of coating apply

also for engraving bits. When it comes to regrinding the most important part

of the tool, the halfening flat, stays unground, so that the coating remains

there.

|